Air Based Microliter Pipetting

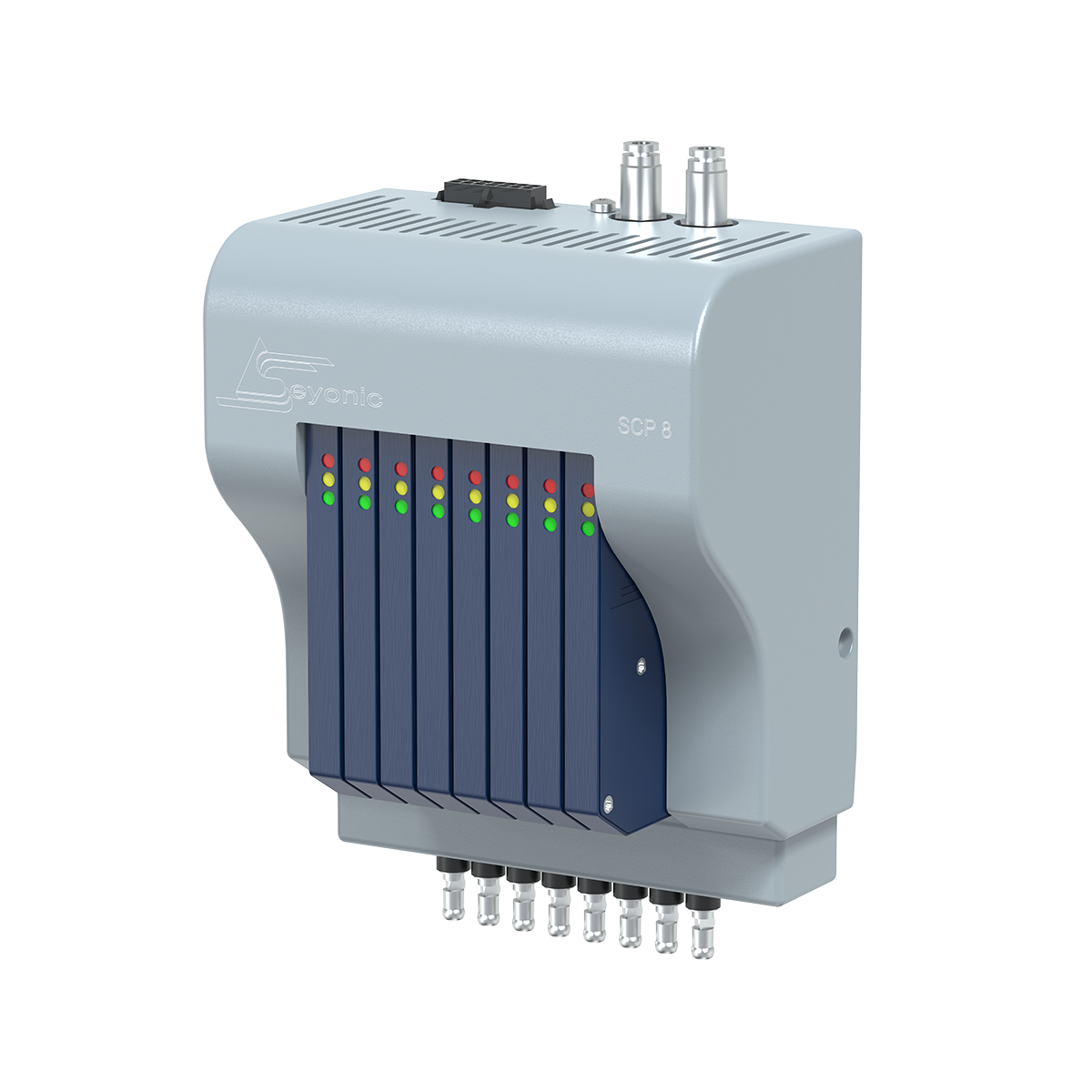

Seyonic Pipetting Technology

Seyonic’s Sensor Controlled Pipetting technology allows very precise monitoring of the liquid handling process. It thus provides not only accurate volume control but also detects pipetting errors in real time. Therefore every pipetting operation can effectively be validated as it is going on. The Process Control Diagnostics allow detection of partial or complete air aspiration while calculating the actually aspirated sample volume. In case of tip clogging, operation is halted immediately to permit the best possibility for recovery.

Process Control Diagnostics are based on analysis of changes in pipetting flow. It is therefore largerly independent of the volume or pipetting speed and does not need to establish guide band reference curves for every possible specific pipetting operation.